INDUSTRY SOLUTIONS

Durable Identification for Defense Applications

For over 60 years, engineers have trusted Metalphoto® photosensitive anodized aluminum for extremely durable equipment and process identification items installed in demanding operating environments.

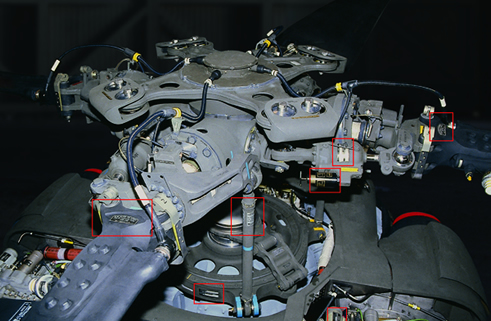

The United States Navy adopted Metalphoto in 1958 for shipboard labels, placards and damage control signs. Since then, Metalphoto has been incorporated into several major Army weapons systems including the Abrams Tank, the Bradley Fighting Vehicle and the HMMWV. Both Marine Corps and Army Depots operate Metalphoto production facilities. All Departments utilize Metalphoto for Item Unique Identification (IUID) barcode labels as specified under MIL-STD-130.

Benefits

Durable Construction

Variable Information Capability

Photographic Resolution Image

Proven Performance

Spotlight

Metalphoto Labels Earn More Top Scores on U.S. Navy Environmental Survivability Test than Any Other Label Material Evaluated

BENEFITS OF USING METALPHOTO:

Because label longevity is critical to IUID, the Naval Surface Warfare Center (NSWC), Corona Division conducted a study to determine the best available label materials. Results showed that Metalphoto® photosensitive anodized aluminum earned more high scores than any other label material evaluated. The study was commissioned to provide an unbiased, government-sponsored comparison of label materials. A total of 73 label materials were submitted across both study phases. The labels were subjected to 38 laboratory tests designed to simulate desert, marine and submarine operating environments, including weather, impact, abrasion, chemical exposure, high-temperatures and salt-water corrosion.

PROVEN DURABILITY:

Not only does Metalphoto have the highest proven scores for durability, Metalphoto can be configured into an assortment of customized label systems to address variety of surface energies and overall applications that can survive a variety of military and industrial applications. Overall Metalphoto earned the highest possible score on 32 of 33 tests for which it was evaluated – more top scores than any other material. For more information about the study, download the synopsis here.

Durable Identification for Aerospace Applications

For over 60 years, engineers have trusted Metalphoto® photosensitive anodized aluminum for extremely durable equipment and process identification items installed in demanding operating environments.

Specified by Boeing, Airbus, Lockheed Martin, NASA and the United States Department of Defense, Metalphoto is used for applications such as nameplates, barcode labels, maintenance schematics, operator control panels, safety protocols and many others.

Benefits

Durable Construction

Variable Information Capability

Photographic Resolution Image

Proven Performance

Spotlight

NADCAP Exemption: Metalphoto photosensitive anodized aluminum has been exempted from NADCAP AC7108 (Audit Criteria for Chemical Processing) by several aerospace Primes and Suppliers.

METALPHOTO – NADCAP EXEMPTED:

The establishment of the National Aerospace & Defense Contractors Accreditation Program (NADCAP) in 1990 was a major step forward for cost and quality in aerospace manufacturing. Since its inception, however, many material suppliers have received exemption from the NADCAP standards. Metalphoto has been exempted from NADCAP by Boeing, Cessna, Hamilton Sundstrand, Lockheed Martin and several others.

WHY METALPHOTO SHOULD BE EXEMPT:

Metalphoto photosensitive anodized aluminum should be exempted from NADCAP AC7108 (Audit Criteria for Chemical Processing). Primes and suppliers who have not taken this action are encouraged to promulgate letters of exemption to affected departments and to organizations in their supply chain. Click here to read about the many reasons why Metalphoto photosensitive anodized aluminum should be exempt and access a draft exemption letter.

SPECIFICATIONS

Boeing Process Specification BAC5875, Fabrication of Aluminum Markers, Instrument Panels, Drawer Front Panels and Fabrication of Metal and Plastic Appliques

LMA-PN010, Fabrication of UID Nameplates for Aircraft Items

Data Systems Division, Specification SMT0022

Johnson Space Center Texas, Space Station Inventory Label Specification – SSP 50007

Durable Identification for Shipbuilding & Marine Applications

For over 60 years, engineers have trusted Metalphoto® photosensitive anodized aluminum for extremely durable equipment and process identification items installed in demanding operating environments.

Specified by Huntington Ingalls, NASSCO, Newport News, the Norwegian Marine Technology Research Institute (Marintek), the United States Navy and many others, Metalphoto is used in applications where labels and nameplates must survive UV exposure, salt spray, abrasion, heat, fuels, cleaning agents, acids, and lubricants while being produced in a timely and cost-efficient manner.

Benefits

Durable Construction

Variable Information Capability

Photographic Resolution Image

Proven Performance

Spotlight

Metalphoto Provides a Durable Identification Solution for Offshore Crane Manufacturer

THE VERSATILITY OF METALPHOTO:

Seatrax experienced the perfect storm of identification issues: extreme operating conditions and short lead times, all with customized graphics for each crane project. Seatrax found Metalphoto photosensitive anodized aluminum to have similar or better durability characteristics than stainless steel with less cost and quicker turnaround times.

PROVEN DURABILITY:

Because the American Petroleum Institute (API) requires that all crane control operations and functions be clearly marked and easily visible by the operator, fading, corrosion and abrasion threaten the readability of identification items, impede safe operation, cost companies downtime and lead to regulatory fines. Therefore, Seatrax specified Metalphoto for its durability – specifically its ability to survive sustained exposure to sunlight/UV, saltspray, abrasion, hydraulic fluids and solvent cleaners. Because of these benefits, Seatrax trusts Metalphoto for durable labels, load charts and operator control panels on their offshore cranes. To learn more click here.

SPECIFICATIONS

DECEMBER 8, 1991

JUNE 2005

AUGUST 2011

Durable Identification for Energy Applications

For over 60 years, engineers have trusted Metalphoto® photosensitive anodized aluminum for extremely durable equipment and process identification items installed in demanding operating environments.

Because of its ability to withstand a range of challenging environmental conditions, Metalphoto is recommended for rating plates, inspection barcodes, maintenance schematics and other exposed identification on solar, wind and hydroelectric energy systems. Metalphoto meets an array of energy specifications including OSHA 1910.145, National Electric Code (NEC) Article 690, ANSI Z535.4 and ISO 3864.

Benefits

Durable Construction

Variable Information Capability

Photographic Resolution Image

Proven Performance

Spotlight

Metalphoto Provides a Durable Identification Solution for Offshore Crane Manufacturer

THE VERSATILITY OF METALPHOTO:

Seatrax experienced the perfect storm of identification issues: extreme operating conditions and short lead times; all with customized graphics for each crane project. Seatrax found Metalphoto photosensitive anodized aluminum to have similar or better durability characteristics than stainless steel, with less cost and quicker turnaround times.

PROVEN DURABILITY:

Because The American Petroleum Institute (API) requires that all crane control operations and functions be clearly marked and easily visible by the operator, fading, corrosion and abrasion threaten the readability of identification items, impede safe operation, cost companies downtime and lead to regulatory fines. Therefore, Seatrax specified Metalphoto for its durability – specifically its ability to survive sustained exposure to sunlight/UV, saltspray, abrasion, hydraulic fluids and solvent cleaners. Because of these benefits, Seatrax trusts Metalphoto for durable labels, load charts and operator control panels on their offshore cranes. To learn more click here.

SPECIFICATIONS

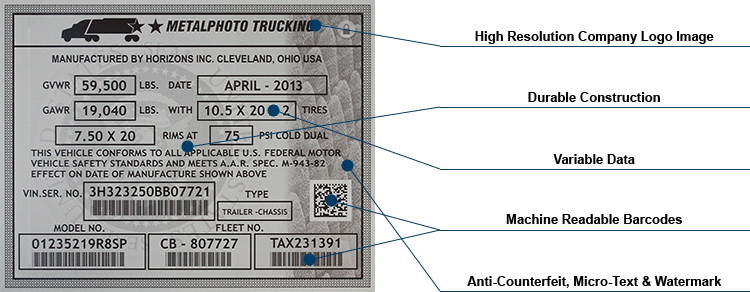

Durable Identification for Transportation Applications

Benefits to the Trailer Manufacturer

- Drive aftermarket revenue: the Intelligent Metalphoto® VIN Tag digitally links to sources for OEM aftermarket parts and service.

- Enhance your selling proposition: the Intelligent Metalphoto® VIN Tag differentiates your trailer from competitors and offers your customers a series of cost-saving benefits.

- Enhance your brand image: the Intelligent Metalphoto® VIN Tag can contain a crisp, high-resolution brand logo image that lasts the life of your trailer – demonstrating the quality of your brand.

Benefits to the Fleet Owner

- Asset Tracking: the Intelligent Metalphoto® VIN Tag ends manual data entry with an asset-specific barcode – reducing labor and errors associated with trailer intake at transfer stations and maintenance facilities.

- Asset Maintenance: the Intelligent Metalphoto® VIN Tag gives the operator and mechanic a service history for each trailer – helping to locate OEM-approved replacement parts and reduce downtime through targeted preventative maintenance.

- Little to No Replacement Costs: the Intelligent Metalphoto® VIN Tag’s durability comes from its image which is sealed inside of the anodized aluminum, providing resistance to road-salt corrosion, abrasion and other conditions that can obscure traditional etched steel plates.

- Proven Track Record: used by several leading trailer manufacturers already, the Intelligent Metalphoto® VIN Tag is already being deployed by leaders in the industry.

Applications

Feature Overview

HERE’S HOW IT WORKS

Durability:

The Intelligent Metalphoto® VIN Tag’s durability comes from Metalphoto’s photographic image which is sealed inside of the anodized aluminum, providing resistance to:

- Sunlight degradation (20+ years)

- Road-salt corrosion (30 days in chamber)

- Abrasion (7,000 cycles on tabor abrader)

- High temperatures (1,000°F)

- Chemical exposure (diesel fuel, hydraulic fluid and several others)

Resolution:

The Intelligent Metalphoto® VIN Tag supports variable data and barcodes because it is a photographic technology. That means:

- Variable data can be embedded in the plate or punched/scribed your location(s)

- Barcodes reduce data entry errors and time – helping your customer track and maintain your product

- Optional two-dimensional QR code can link mechanics to a maintenance history and parts list of OEM-approved aftermarket parts

- Optional anti-counterfeit features such as watermark and micro-print verify authenticity of your product

In addition to VIN Tags, manufactures use Metalphoto for these permeant identification items:

- CSC Safety Approval Plates

- ISO 6346/BIC intermodal shipping container nameplates

- And other durable nameplates, maintenance schematics and labels

Durable Identification for Heavy Equipment Applications

For over 60 years, engineers have trusted Metalphoto® photosensitive anodized aluminum for extremely durable equipment and process identification items installed in demanding operating environments.

Specified by several leading equipment and defense OEMs, Metalphoto is used for applications such as nameplates, barcode labels, maintenance schematics, operator control panels, safety protocols and many others.

Benefits

Durable Construction

Variable Information Capability

Photographic Resolution Image

Proven Performance

Spotlight

Heavy-Duty Equipment Requires Heavy-Duty Panels

METALPHOTO ENDURES SUBSTANTIAL ABUSE:

Link-Belt Construction Equipment Company is a leader in the design and manufacture of telescopic and lattice boom cranes. One of the requirements for the cab componentry in their construction vehicles calls for panels that display universal symbols for operation. The parts are expected to endure substantial abuse out on the job site – suffering forceful impacts as well as regular exposure to abrasives, UV and extreme heat or cold. Link-Belt uses Metalphoto®, for its HTC, RTC and ATC equipment. Metalphoto produces high-resolution graphics and features a sapphire-hard anodic layer that is impervious to weather. That anodic layer also provides superior resistance to UV, abrasion, extreme temperatures, and chemicals.

SPECIFICATIONS

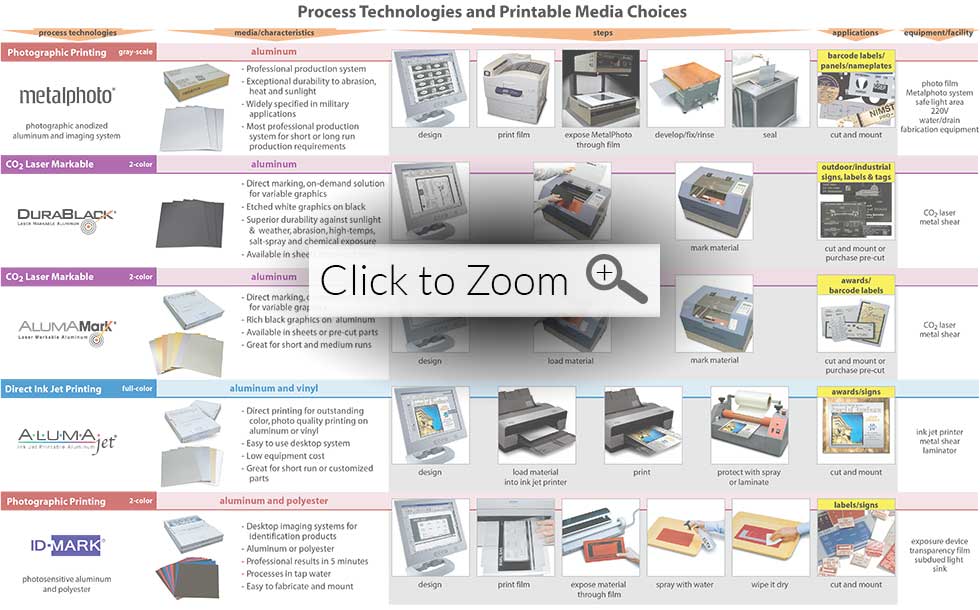

Photo Quality Images on Real Metal

Horizons Imaging Systems Group offers several unique micro-coated aluminum based products for the recognition industry. Each material is available in a variety of finishes (satin, matte, brushed, etc.) and can be processed at your location with equipment you may already own!

Choose the material the best fits your application(s). Visit each product page or contact us to learn more.

PHOTO QUALITY IMAGES ON REAL METAL WITH ANY CO2 LASER WITHOUT ETCHING, ENGRAVING OR CHEMICALS.

AlumaMark is specialized aluminum that lets one create high-resolution images on real metal. Because AlumaMark is not etched or engraved, but rather marked through a thermal reaction with the heat of a laser, it creates lighter marks and halftone shades.

PRINT FULL-COLOR, PHOTO-QUALITY IMAGES DIRECTLY ONTO REAL METAL WITH A STANDARD INKJET PRINTER.

AlumaJet is anodized aluminum that has been specially developed so that you may print brilliant, full-color, high-resolution images directly to the metal using a standard ink-jet printer.

TRUSTED WHERE PERMANENT IDENTIFICATION IS CRITICAL.

Plaque & Award manufacturers who expand into outdoor signage, memorial plaques, and industrial nameplates find that Metalphoto provides a valuable revenue stream.

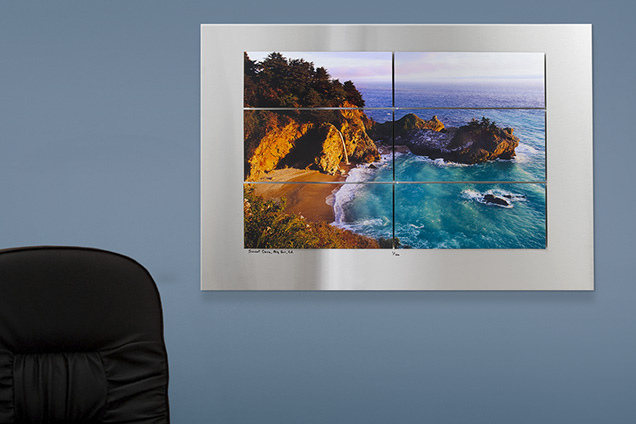

Durable Identification for Architectural Signage

Architects and designers use our materials for high-value outdoor and indoor signage projects such as wayfinding signs, blueprint reproductions, building certification plaques and donor recognition plates.

Architects and designers use our materials for high-value outdoor and indoor signage projects such as wayfinding signs, blueprint reproductions, building certification plaques and donor recognition plates.

Metalphoto® photosensitive anodized aluminum allows you to capture rich, photographic quality images inside of metal – providing unmatched longevity and the durable, modern look of anodized aluminum. Because Metalphoto is a photographic process, its image resolution, clarity and durability are superior to printed or etched signs. The Metalphoto image is cleanable, graffiti proof and impervious to sunlight and abrasion. Available in five finishes and thicknesses of .003” to .125”. Metalphoto is designed for permanency – it will not fade or need to be replaced. If replacement is desired, Metalphoto is 100% recyclable. Customized metal signage can be made to your specifications.

Benefits

Durable Construction

Variable Information Capability

Photographic Resolution Image

Proven Performance

Spotlight

Award-winning Mariemont School Foundation chose Metalphoto photosensitive anodized aluminum for permanent images to last a lifetime.

METALPHOTO OFFERS SHARP BLACK GRAPHICS AND SUPERIOR DURABILITY :

In 2012, the Mariemont School Foundation set out to create an outdoor structure that would recognize the district’s generous supporters, display the faces of local students and faculty, and inspire others in the community to give. To create photo images with sharp black graphics and superior durability, White Design Studio turned to Metalphoto.

PHOTOGRAPHIC RESOLUTION AND GRAFFITI-RESISTANCE:

Metalphoto anodized aluminum is the only material that could give White Design Studio the photo resolution they wanted with the durability they needed for this project. Given its location on a busy city street, the donor recognition wall also benefits from another Metalphoto characteristic — it is inherently graffiti-resistant. Click here to learn more.

Horizons ISG is a member of the Society for Environmental Graphic Design

On-Site Processing

All Horizons ISG substrates can be imaged at your location where and when needed or purchased from worldwide network of approved suppliers. Please contact your ISG sales representative at info@horizonsisg.com for information about purchasing new or upgrading existing processing equipment.